TechBuzz

Waste and Pollution Control : Enabling compliance with environmental regulations, reducing hazardous emissions

Machinery for waste and pollution control plays a critical role in the jewellery industry by enabling compliance with environmental regulations, reducing hazardous emissions, and recovering valuable metals from scraps, thereby minimizing ecological damage and operational costs.

Jewellery manufacturing generates significant waste from processes like mining, refining, casting, and polishing, including toxic chemicals, heavy metals, and wastewater that pollute water and soil. Air pollution from smelting releases sulphur dioxide, while e-waste and workshop sweeps contain recoverable gold and silver if not managed properly. In India, stricter DGFT wastage norms effective January 2025 and CPCB guidelines mandate pollution controls to prevent ecosystem harm.

Essential Machinery Types

Refining and recovery systems: Automated aqua regia plants and e-waste recycling machines extract 99%+ of gold/silver from scraps, sweeps, and plating waste, cutting landfill disposal.

Air pollution controls: Fume scrubbers, vacuum casting, and induction melters with inert gas capture acidic fumes and particulates during rhodium polishing and assaying.

Wastewater treatment: On-site systems with e-coating and real-time monitoring (CEMS/OCEMS) treat chemical runoff from plating, ensuring zero harmful discharge per MPCB consents.

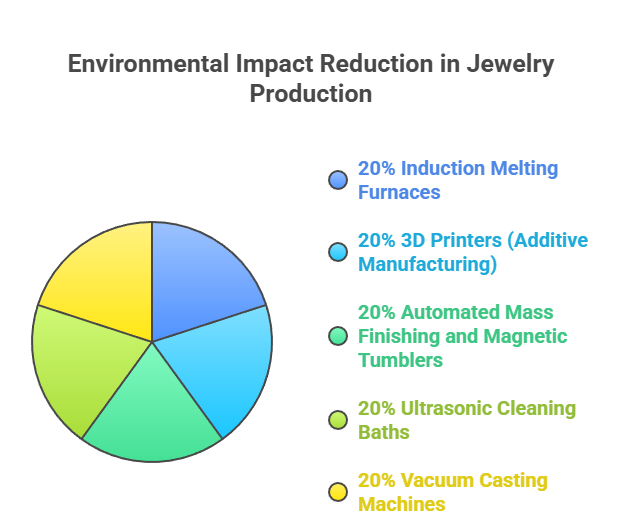

Several types of machinery and associated technologies are used in the jewelry industry to reduce pollution, primarily by improving material recovery, enhancing energy efficiency, and replacing hazardous chemicals.

Machinery for Waste and Pollution Control

- Precious Metal Recovery Incinerators:┬ĀSpecialized incinerators are used to burn organic waste, such as polishing dusts and floor sweepings, leaving behind ash containing precious metals that can be safely recovered. These systems often include integrated┬Āair pollution control equipment┬Ālike wet venturi scrubbers and bag filters to capture escaping dust particles and neutralize harmful gases.

- Fume Control and Acid Neutralization Scrubbers:┬ĀThese systems remove harmful materials from industrial exhaust gases, such as those produced during acid leaching or refining processes, before they are released into the environment. They work by conveying fumes into washing columns where harmful substances are neutralized.

- Wastewater Filtration Systems:┬ĀAdvanced filtration systems, some using premium-grade resin, are designed to extract trace amounts of gold and silver particles from wastewater generated during refining and cleaning processes. This ensures a fully loss-free process and prevents water pollution.

- Enclosed Devestment Units:┬ĀInstead of manual knockout, enclosed dry flask strippers with dust collection systems or high-pressure water jet wash cabinets are used to remove investment material from cast trees. This prevents worker exposure to harmful silica dust and contains the waste for proper disposal.┬Ā

Production Machinery for Efficiency and Material Reduction

- Induction Melting Furnaces:┬ĀThese electric furnaces use electromagnetic induction to melt metals efficiently, avoiding the fossil fuels used in traditional methods. They have no open flame and are smoke-free, significantly reducing greenhouse gas emissions and air pollution.

- 3D Printers (Additive Manufacturing):┬ĀBy creating jewelry directly from digital designs using only the necessary material (wax, resin, or metal powder), 3D printing significantly minimizes material waste. Excess metal powder can be collected and reused, reducing the demand for newly mined materials.

- Automated Mass Finishing and Magnetic Tumblers:┬ĀThese machines use fine steel pins or various media to polish jewelry without the need for highly toxic chemicals like cyanide or strong acids, which were traditionally used for fire scale removal.

- Ultrasonic Cleaning Baths:┬ĀThese machines use high-frequency sound waves and mild, often eco-friendly, cleaning solutions (e.g., ammonium phosphate or hydrogen peroxide) to remove dirt and oxidation, eliminating the need for hazardous cleaning agents and strong acids.

- Vacuum Casting Machines:┬ĀModern vacuum and centrifugal casting machines prevent oxidation during the casting process by using inert gases, which reduces or eliminates the need for subsequent acid cleaning and polishing steps.┬Ā

These technologies, combined with the use of recycled metals, ethically sourced lab-grown diamonds, and general energy-efficient practices (like LED lighting), are transforming the industry towards more sustainable operations.

JB Insights

Jewellery machinery is vital investment for global competitiveness

JBExlusive

Jewel Buzz recently hosted a high-level panel featuring the titans of the jewelry manufacturing industry to discuss the significance of the JMAIIE 2026. The Panel of Stalwarts comprised :K Srinivasan: Chairman, Emerald Group,Dr. Chetan Kumar: CMD, Lakshmi Diamonds, Bengaluru Nitesh Jain, MD, Purple Jewels Private Limited,Nikhil Ranavat: Director, AR Gold Private Limited & Director, Swarnshilp Chains and Jewels Pvt Ltd

The discussion highlighted how technology is no longer an optional expense but a vital investment for global competitiveness. The importance of machinery was summed by said K Srinivasan: Investing in machinery is not an expenditure; it is an investment.

Key Objectives for JMAIIE 2026

The leaders identified several critical reasons for attending the expo, emphasizing that the “machinery-only” focus of JMAIIE allows for deep concentration without the distractions of finished jewelry.

- Technology Upgradation:┬Ā K Srinivasan emphasized that with 41 years in the field, he views quality machinery as the foundation for working with all gold purities (from 9k to 22k) and silver. Continuous updating is required to stay relevant.

- Cost & Loss Reduction:┬Ā Nikhil Ranawat pointed out that with rising gold prices, the priority is minimizing manufacturing losses. Even recovering an extra 1% of gold through better technology significantly impacts the bottom line.

- Weight & Aesthetics: Dr. Chetan Kumar noted the industry’s shift toward both ultra-lightweight and complex fashionable jewelry, both of which require advanced precision tools.

- Production Efficiency:┬Ā Nitesh Jain highlighted the need for robust, “non-breakdown” machines to keep manufacturing costs low for the end consumer.

The State of “Make in India” Machinery

The panel offered a candid assessment of domestic vs. international machinery standards:

| Strengths of Indian Machinery | Areas for Improvement |

| Outstanding quality in Enameling, Casting Furnaces, and Buffing Machines. | Chain-making technology still lags behind global standards. |

| Excellence in CAD/CAM software and implementation. | Need for more robust, long-term durability to match Italian/Western builds. |

| High value-for-money and improving after-sales service. | Consistency in high-end finishing for luxury products. |

Future Outlook

The industry leaders called for a strategic shift to align with the Atmanirbhar Bharat (Self-Reliant India) vision.

- Technology Hubs: Dr. Chetan Kumar said government support was imperative and proposed the creation of a dedicated Technology Park for the jewelry industry where manufacturers and AI researchers can collaborate on new machinery.

- Skill Development:┬Ā Nitesh Jain warned that high-tech machines are useless without a skilled workforce trained to operate them. A cultural shift from traditional handmade methods to tech-driven manufacturing is essential.

- Global Ambitions: With the conclusion of various FTAs (Free Trade Agreements), the panel believes that superior technology will allow India to truly become the “Jeweler to the World.”

Conclusion

JMAIIE 2026 stands as a pivotal platform for the industry. The consensus is clear: the future of Indian jewelry lies in the marriage of traditional hand-craftsmanship and cutting-edge technology.

-

DiamondBuzz6 hours ago

DiamondBuzz6 hours agoBotswana Diamonds rebrands as Botswana Minerals PLC

-

DiamondBuzz6 hours ago

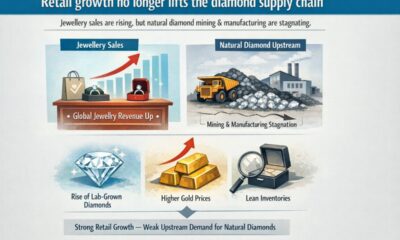

DiamondBuzz6 hours agoDespite revenue growth in jewellery sector, natural diamond upstream sees stagnation

-

International News8 hours ago

International News8 hours agoIndia Pavilion at HK twin shows showcases exceptional craftsmanship

-

International News8 hours ago

International News8 hours agoGold continues to get strength on the Middle East conflict