TechBuzz

Groundbreaking Collection Highlights Possibilities for 3D-Printed Platinum Jewellery Design

Platinum Guild International Leads Efforts to Expand Platinumãs Production Capabilities Using 3D Printing Technology with Tû¿saire Collection by Maeve Gillies

Platinum Guild International (PGI) continues to champion technological advancements in platinum jewellery design and fabrication with a ground-breaking development in 3D printing. The innovative Tû¿saire collection, created by Scottish-American jewellery designer Maeve Gillies using 3D printing technology, is the first platinum-based collection of its kind to be launched commercially.

The Tû¿saire Collection is named after the Scottish Gaelic word for ãpioneerã and features jewellery made from platinum and titanium, including necklaces, bracelets, earrings, and rings that highlight the potential of 3D printed platinum in the realm of jewellery design and fabrication.

While sharing this latest development in the platinum jewellery market at ORIGINALLUXURYãs 5thô Roundtable event in Geneva in May 2025, which brought together 150 luxury, technology and finance stakeholders, PGIãs CEO Tim Schlick explained, ãWe needed to put 3D printing of platinum to the test, to identify the advantages and challenges, in the hope of expediting the technologyãs application in making precious jewellery and its ability to create novel designs and experiences. There is no doubt additive manufacturing will be very important for the future of jewellery as it unlocks so many new possibilities.ã

While 3D printing was already an established technology for jewellery production, the launch of the Tû¿saire collection beautifully demonstrates the decorative, scale and structural potential for 3D printed platinum jewellery. For example, the 3D printing and precious metal powder technology used have enabled the crafting of intricate, unique shapes that would be impossible to achieve otherwise, such as lattices, hollow structures and detailed textures. As Mr. Schlick noted during the workshop, ãWe are just beginning to understand how platinum can create new emotional and practical value in 3D printing, not only through how it looks, but how it is made, owned, and experienced.ã

ãThis moment marks a pivotal opportunity for platinum to redefine its role in luxury through creativity, cross-sector collaboration, and future-ready innovation,ã said Margot Stuart, co-founder of ORIGINALLUXURY and OriginAll S.A..

ô ãAs most of my work is in diamond bridal jewellery fabrication, I learned through experience that platinum is the ideal bridal metal due to its strength, resilience, and suitability for diamond design innovation. For this 3D-printed jewellery collection, my knowledge of platinum was invaluable in allowing me to design new solutions with the printing technology, helping to transform platinum into new jewellery looks and categories,ã said Gillies about her experience designing and developing the 3D-printed jewellery.

The direct metal printing of the platinum pieces was completed by the Italian-based company ProGold, which utilises metal laser powder bed fusion and other technologies to develop and produce parts from precious metals for a range of industries.

ãDue to platinum’s high tenacity, strength and high melting temperature, it enables the highest quality of structural integrity with precise heat control. Its good light absorption and low reflectivity also make platinum a comparatively energy-efficient metal for printing with lasers.” ô Tai Wong, Director of Innovations and Product Development at PGI shares. ãPlatinumãs metal attributes are superior for processes like laser powder bed fusion, and we found the best of platinumãs strength and shine are optimised by direct metal printing.ã

The technology catapults platinum into new types of jewellery by enabling the creation of larger silhouettes that were previously impossible because platinum is traditionally a heavier, denser, and more expensive metal. However, platinum is currently highly desirable, partly because its price makes it more affordable than gold.

ãThis is such an interesting time in the industry because technologies are coming in thick and fast. At the same time, craft has never been more important for people to preserve and understand the process and the possibilities of new materials and new ways of expressing and pushing more towards what platinum can do,ã added Ms. Gillies.

TechBuzz

Waste and Pollution Control : Enabling compliance with environmental regulations, reducing hazardous emissions

Machinery for waste and pollution control plays a critical role in the jewellery industry by enabling compliance with environmental regulations, reducing hazardous emissions, and recovering valuable metals from scraps, thereby minimizing ecological damage and operational costs.

Jewellery manufacturing generates significant waste from processes like mining, refining, casting, and polishing, including toxic chemicals, heavy metals, and wastewater that pollute water and soil. Air pollution from smelting releases sulphur dioxide, while e-waste and workshop sweeps contain recoverable gold and silver if not managed properly. In India, stricter DGFT wastage norms effective January 2025 and CPCB guidelines mandate pollution controls to prevent ecosystem harm.

Essential Machinery Types

Refining and recovery systems: Automated aqua regia plants and e-waste recycling machines extract 99%+ of gold/silver from scraps, sweeps, and plating waste, cutting landfill disposal.

Air pollution controls: Fume scrubbers, vacuum casting, and induction melters with inert gas capture acidic fumes and particulates during rhodium polishing and assaying.

Wastewater treatment: On-site systems with e-coating and real-time monitoring (CEMS/OCEMS) treat chemical runoff from plating, ensuring zero harmful discharge per MPCB consents.

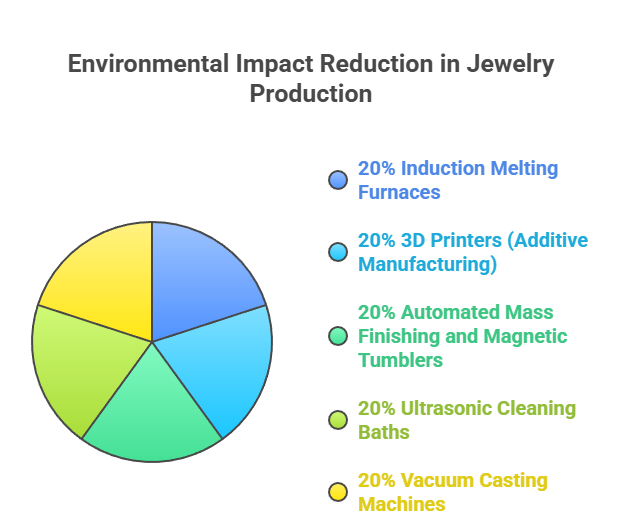

Several types of machinery and associated technologies are used in the jewelry industry to reduce pollution, primarily by improving material recovery, enhancing energy efficiency, and replacing hazardous chemicals.

Machinery for Waste and Pollution Control

- Precious Metal Recovery Incinerators:ô Specialized incinerators are used to burn organic waste, such as polishing dusts and floor sweepings, leaving behind ash containing precious metals that can be safely recovered. These systems often include integratedô air pollution control equipmentô like wet venturi scrubbers and bag filters to capture escaping dust particles and neutralize harmful gases.

- Fume Control and Acid Neutralization Scrubbers:ô These systems remove harmful materials from industrial exhaust gases, such as those produced during acid leaching or refining processes, before they are released into the environment. They work by conveying fumes into washing columns where harmful substances are neutralized.

- Wastewater Filtration Systems:ô Advanced filtration systems, some using premium-grade resin, are designed to extract trace amounts of gold and silver particles from wastewater generated during refining and cleaning processes. This ensures a fully loss-free process and prevents water pollution.

- Enclosed Devestment Units:ô Instead of manual knockout, enclosed dry flask strippers with dust collection systems or high-pressure water jet wash cabinets are used to remove investment material from cast trees. This prevents worker exposure to harmful silica dust and contains the waste for proper disposal.ô

Production Machinery for Efficiency and Material Reduction

- Induction Melting Furnaces:ô These electric furnaces use electromagnetic induction to melt metals efficiently, avoiding the fossil fuels used in traditional methods. They have no open flame and are smoke-free, significantly reducing greenhouse gas emissions and air pollution.

- 3D Printers (Additive Manufacturing):ô By creating jewelry directly from digital designs using only the necessary material (wax, resin, or metal powder), 3D printing significantly minimizes material waste. Excess metal powder can be collected and reused, reducing the demand for newly mined materials.

- Automated Mass Finishing and Magnetic Tumblers:ô These machines use fine steel pins or various media to polish jewelry without the need for highly toxic chemicals like cyanide or strong acids, which were traditionally used for fire scale removal.

- Ultrasonic Cleaning Baths:ô These machines use high-frequency sound waves and mild, often eco-friendly, cleaning solutions (e.g., ammonium phosphate or hydrogen peroxide) to remove dirt and oxidation, eliminating the need for hazardous cleaning agents and strong acids.

- Vacuum Casting Machines:ô Modern vacuum and centrifugal casting machines prevent oxidation during the casting process by using inert gases, which reduces or eliminates the need for subsequent acid cleaning and polishing steps.ô

These technologies, combined with the use of recycled metals, ethically sourced lab-grown diamonds, and general energy-efficient practices (like LED lighting), are transforming the industry towards more sustainable operations.

-

GlamBuzz2 weeks ago

GlamBuzz2 weeks agoGIVA Launches ãGlow in Motionã, Unveils New Jewellery Collection Fronted by Barkha Singh

-

International News2 weeks ago

International News2 weeks agoSilver retraces down on margin hike pressure AUGMONT BULLION REPORT

-

JB Insights2 weeks ago

JB Insights2 weeks agoThe JewelBuzz E-zine: Your Fortnightly Pulse of the Jewellery Industry

-

JB Insights2 weeks ago

JB Insights2 weeks agoIIJS Bharat Signature 2026 set to open the year with scale, innovation and global momentum