TechBuzz

Doit Designs India Pvt. Ltd. Revolutionises the Jewellery Industry with Its Digital Design-to-Production Ecosystem

From global designer-manufacturer collaborations to gold-saving 3D technologies, Doit Designs India Pvt. Ltd. empowers the jewellery sector with innovation, efficiency, and scalability.

Operates in the jewellery industry, providing a digital ecosystem that bridges designers and manufacturers. Their platform helps professionals showcase, optimize, and sell jewellery designs efficiently.

Key Services

D4J (Designs For Jewellery) Marketplace:

- Global Hub ŌĆō Connects Indian & international designers with verified manufacturers worldwide.

- Multi-Format Support ŌĆō Accepts & delivers designs in STL, 3DM, WAX (currently limited to India), and other industry-standard file formats.

- Secure Transactions ŌĆō Features escrow-style payments, IP protection, and dispute resolution for smooth deals.

- Insights & Analytics ŌĆō Dashboard with sales trends, design popularity, and market demand data.

- Scalable Pricing ŌĆō Flexible subscription plans catering to freelancers, SMEs, and large enterprises.

Render Jewellery

- Photorealistic Visuals ŌĆō Generates high-resolution, lifelike 3D renders of jewellery pieces.

- Design Validation ŌĆō Enables designers and clients to review gemstone sparkle, metal finish, and proportions before production.

- Marketing & Sales Boost ŌĆō Provides ready-to-use images for e-commerce listings, catalogues, social media, and advertising, speeding time-to-market.

- Cost & Time Efficiency ŌĆō Reduces need for physical prototypes, saving material, labour, and turnaround time.

MIRA 3D

- Gold Saving Technology (MiraAkar)

- Scooping: Removes hidden inner gold while preserving design strength.

- 3D Print Ready ŌĆō Exports clean STL/SLC files compatible with all leading 3D printers.

- Smart File Fixing & Auto-Support (MiraPro) ŌĆō Automatically detects geometry issues, repairs them, and generates optimal supports.

- Instant Resizing Tools ŌĆō Quickly adjust rings, bangles, and bracelets with precision.

- Expert Assistance ŌĆō Offers professional guidance for additive manufacturing and production automation.

Why It Matters

- Global Reach ŌĆō Empowers Indian and international designers to showcase & sell worldwide.

- Material Efficiency ŌĆō Gold weight reduction significantly cuts costs.

- Production-Ready ŌĆō Ensures a seamless transition from design to manufacturing.

TechBuzz

Waste and Pollution Control : Enabling compliance with environmental regulations, reducing hazardous emissions

Machinery for waste and pollution control plays a critical role in the jewellery industry by enabling compliance with environmental regulations, reducing hazardous emissions, and recovering valuable metals from scraps, thereby minimizing ecological damage and operational costs.

Jewellery manufacturing generates significant waste from processes like mining, refining, casting, and polishing, including toxic chemicals, heavy metals, and wastewater that pollute water and soil. Air pollution from smelting releases sulphur dioxide, while e-waste and workshop sweeps contain recoverable gold and silver if not managed properly. In India, stricter DGFT wastage norms effective January 2025 and CPCB guidelines mandate pollution controls to prevent ecosystem harm.

Essential Machinery Types

Refining and recovery systems: Automated aqua regia plants and e-waste recycling machines extract 99%+ of gold/silver from scraps, sweeps, and plating waste, cutting landfill disposal.

Air pollution controls: Fume scrubbers, vacuum casting, and induction melters with inert gas capture acidic fumes and particulates during rhodium polishing and assaying.

Wastewater treatment: On-site systems with e-coating and real-time monitoring (CEMS/OCEMS) treat chemical runoff from plating, ensuring zero harmful discharge per MPCB consents.

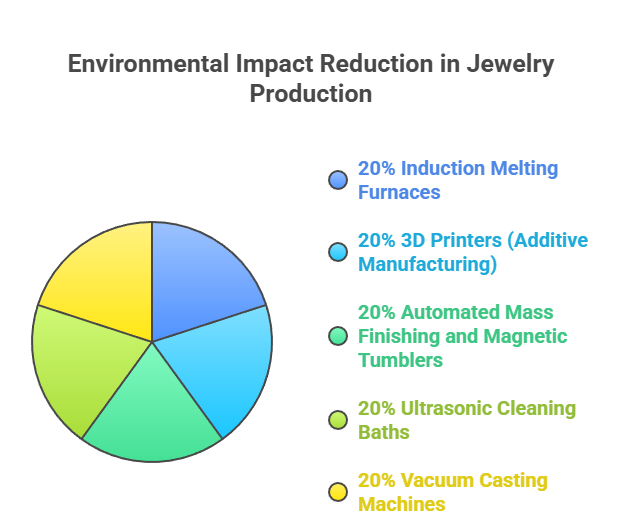

Several types of machinery and associated technologies are used in the jewelry industry to reduce pollution, primarily by improving material recovery, enhancing energy efficiency, and replacing hazardous chemicals.

Machinery for Waste and Pollution Control

- Precious Metal Recovery Incinerators:┬ĀSpecialized incinerators are used to burn organic waste, such as polishing dusts and floor sweepings, leaving behind ash containing precious metals that can be safely recovered. These systems often include integrated┬Āair pollution control equipment┬Ālike wet venturi scrubbers and bag filters to capture escaping dust particles and neutralize harmful gases.

- Fume Control and Acid Neutralization Scrubbers:┬ĀThese systems remove harmful materials from industrial exhaust gases, such as those produced during acid leaching or refining processes, before they are released into the environment. They work by conveying fumes into washing columns where harmful substances are neutralized.

- Wastewater Filtration Systems:┬ĀAdvanced filtration systems, some using premium-grade resin, are designed to extract trace amounts of gold and silver particles from wastewater generated during refining and cleaning processes. This ensures a fully loss-free process and prevents water pollution.

- Enclosed Devestment Units:┬ĀInstead of manual knockout, enclosed dry flask strippers with dust collection systems or high-pressure water jet wash cabinets are used to remove investment material from cast trees. This prevents worker exposure to harmful silica dust and contains the waste for proper disposal.┬Ā

Production Machinery for Efficiency and Material Reduction

- Induction Melting Furnaces:┬ĀThese electric furnaces use electromagnetic induction to melt metals efficiently, avoiding the fossil fuels used in traditional methods. They have no open flame and are smoke-free, significantly reducing greenhouse gas emissions and air pollution.

- 3D Printers (Additive Manufacturing):┬ĀBy creating jewelry directly from digital designs using only the necessary material (wax, resin, or metal powder), 3D printing significantly minimizes material waste. Excess metal powder can be collected and reused, reducing the demand for newly mined materials.

- Automated Mass Finishing and Magnetic Tumblers:┬ĀThese machines use fine steel pins or various media to polish jewelry without the need for highly toxic chemicals like cyanide or strong acids, which were traditionally used for fire scale removal.

- Ultrasonic Cleaning Baths:┬ĀThese machines use high-frequency sound waves and mild, often eco-friendly, cleaning solutions (e.g., ammonium phosphate or hydrogen peroxide) to remove dirt and oxidation, eliminating the need for hazardous cleaning agents and strong acids.

- Vacuum Casting Machines:┬ĀModern vacuum and centrifugal casting machines prevent oxidation during the casting process by using inert gases, which reduces or eliminates the need for subsequent acid cleaning and polishing steps.┬Ā

These technologies, combined with the use of recycled metals, ethically sourced lab-grown diamonds, and general energy-efficient practices (like LED lighting), are transforming the industry towards more sustainable operations.

-

GlamBuzz2 weeks ago

GlamBuzz2 weeks agoGIVA Launches ŌĆśGlow in MotionŌĆÖ, Unveils New Jewellery Collection Fronted by Barkha Singh

-

International News2 weeks ago

International News2 weeks agoSilver retraces down on margin hike pressure AUGMONT BULLION REPORT

-

JB Insights2 weeks ago

JB Insights2 weeks agoThe JewelBuzz E-zine: Your Fortnightly Pulse of the Jewellery Industry

-

JB Insights2 weeks ago

JB Insights2 weeks agoIIJS Bharat Signature 2026 set to open the year with scale, innovation and global momentum