TechBuzz

Alloys and Metal Innovation in Jewellery Manufacturing

The jewellery manufacturing landscape in 2025 is experiencing a significant evolution in metal and alloy utilization, driven by shifting consumer preferences toward versatility, sustainability, and personalized design. This report examines the key trends reshaping how manufacturers approach metal selection and alloy development.

Mixed Metal Revolution

The industry is witnessing a decisive move away from traditional single-metal matching sets toward deliberately eclectic combinations. Manufacturers are increasingly working with multiple metals within individual pieces, creating visual interest through material contrast.

Popular Combinations:

- Yellow gold paired with white gold or platinum

- Rose gold integrated with silver elements

- Antique or oxidized silver accents on gold foundations

- Three-tone designs incorporating warm, cool, and neutral metals simultaneously

Application Areas: This trend manifests most prominently in layered necklaces, stacked ring sets, and statement pieces designed to anchor mixed-metal wardrobes. The approach enables consumers to wear jewelry across occasions without concern for metal matching, fundamentally changing how people build their

Primary Gold Alloy Constituents:

- Yellow Gold Alloys: Typically combine pure gold (ranging from 37.5% for 9K to 75% for 18K) with copper and silver. The ratio determines both karat purity and color depth. Higher copper content creates warmer, more reddish tones.

- White Gold Alloys: Blend pure gold with white metals such as palladium, nickel, zinc, or silver. Palladium-based white gold (more expensive but hypoallergenic) is increasingly preferred over nickel-containing formulations due to allergy concerns. Most white gold receives rhodium plating for enhanced whiteness and durability.

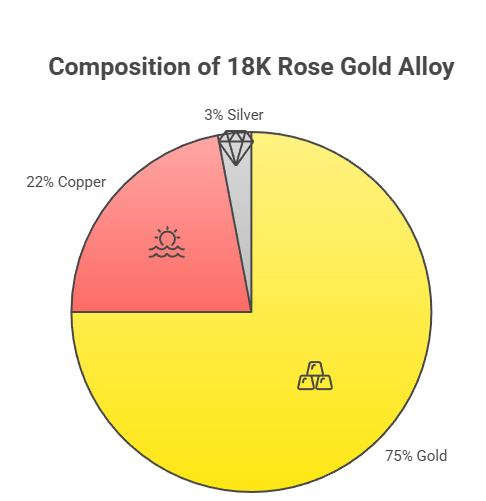

- Rose Gold Alloys: Achieve their distinctive pink hue through higher copper proportions in the alloy mix. An 18K rose gold might contain 75% gold, 22% copper, and 3% silver, though ratios vary by desired intensity of color.

Silver Alloy Components:

- Sterling Silver: The industry standard consists of 92.5% pure silver alloyed with 7.5% copper, which provides necessary hardness while maintaining silver’s characteristic appearance.

- Argentium Silver: A modern alloy replacing some copper content with germanium, offering improved tarnish resistance and increased durability—particularly valuable for mixed-metal designs.

Platinum Group Alloys:

Platinum jewellery typically contains 90-95% pure platinum alloyed with other platinum group metals (ruthenium, iridium, or palladium) to enhance workability and durability while maintaining the metal’s prestigious white appearance and hypoallergenic properties.

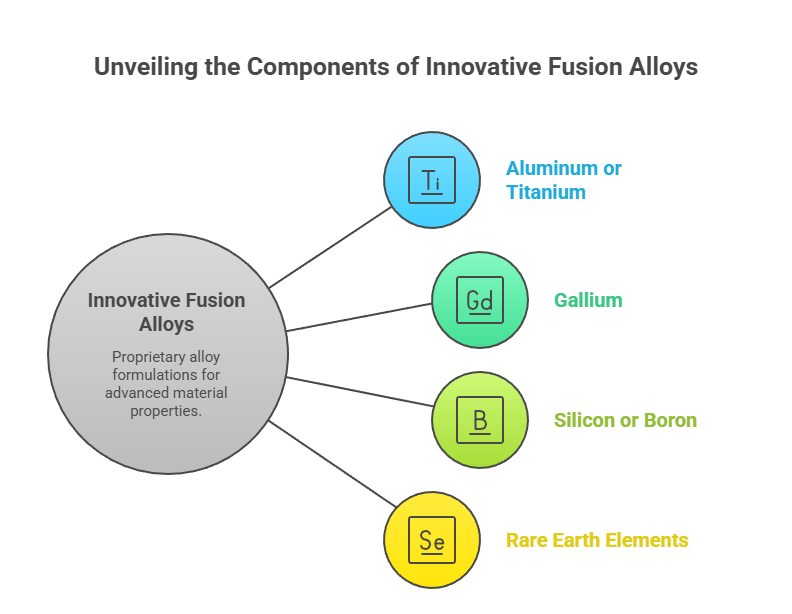

Innovative Fusion Alloy Development:

Manufacturers are now experimenting with proprietary alloy formulations that incorporate:

- Aluminum or titanium in trace amounts to reduce weight

- Gallium to improve casting properties

- Silicon or boron for enhanced strength-to-weight ratios

- Rare earth elements in minute quantities for specialized color effects

These experimental constituents enable the lightweight, fusion designs gaining prominence in 2025 collections.

Lightweight and Fusion Alloy Innovation

Manufacturers are developing proprietary alloys that maintain precious metal content and visual appeal while reducing weight. This innovation addresses consumer demands for all-day wearability, particularly in gold jewelry where traditional density can limit design possibilities.

Technical Advances: The development of fusion alloys allows jewelers to create larger, more dramatic pieces that remain comfortable for extended wear. These alloys balance structural integrity with reduced mass, enabling designs that would be impractical in traditional solid gold or platinum.

Economic and Creative Benefits: Beyond comfort, these lightweight alternatives offer cost advantages that make premium metal jewelry accessible to broader markets while giving designers freedom to explore bolder, more sculptural forms previously limited by weight considerations.

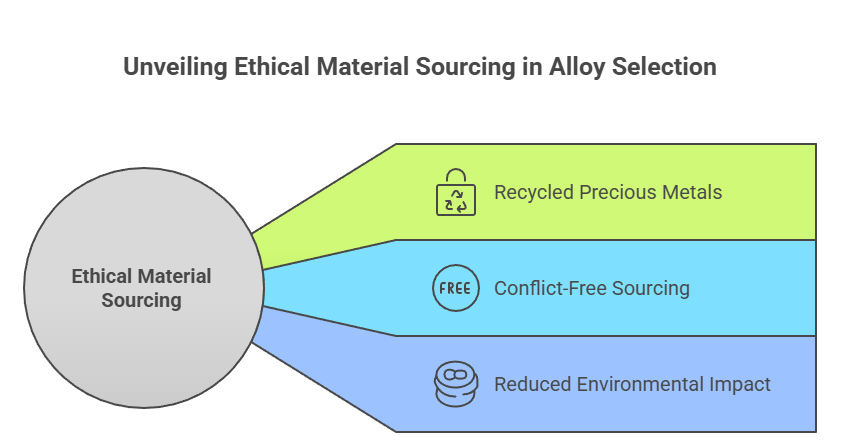

Sustainability Integration

Ethical Material Sourcing

Environmental and social responsibility now directly influences alloy selection and metal sourcing decisions. Manufacturers increasingly prioritize:

- Recycled precious metals in alloy formulations

- Conflict-free sourcing with transparent supply chains

- Reduced environmental impact in refining and production processes

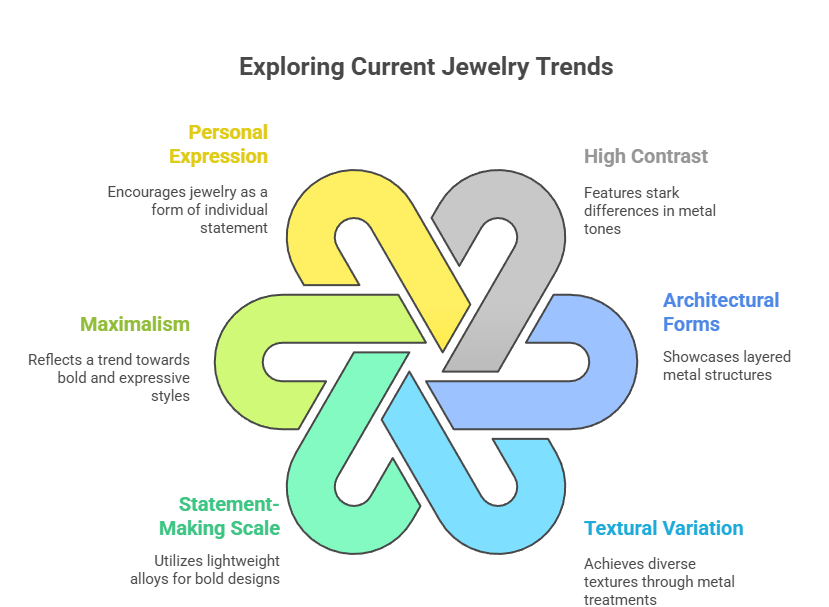

Aesthetic Direction: Bold Contrast and Visual Complexity

Design Philosophy Shift

The 2025 aesthetic embraces intentional contrasts rather than subtle harmony. Designers exploit the visual tension between warm and cool metals, polished and matte finishes, and contemporary forms with traditional metalwork techniques.

Characteristics of Current Collections:

- High contrast between metal tones within single pieces

- Architectural forms that showcase multiple metal layers

- Textural variation created through different metal treatments

- Statement-making scale enabled by lightweight alloy advances

This direction reflects broader fashion trends toward maximalism and personal expression, where jewelry serves as conversation pieces rather than understated accents.

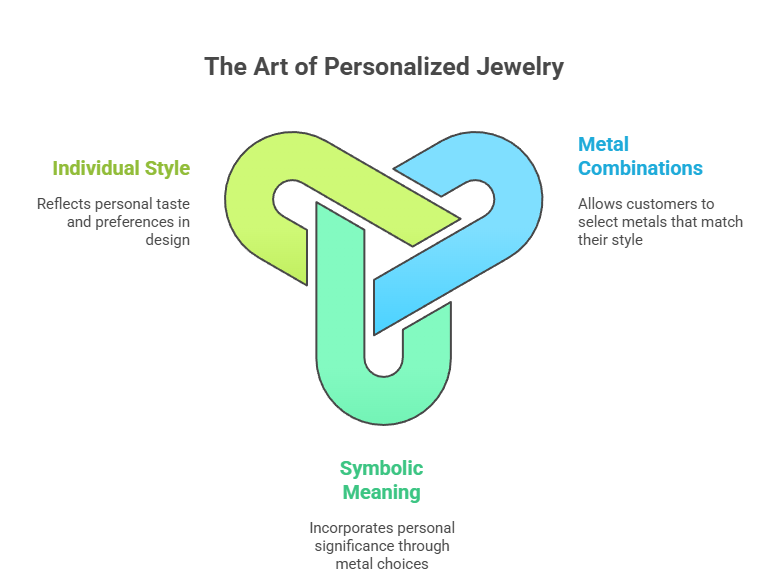

Customization and Personalization

The flexibility of mixed-metal approaches supports the strong consumer demand for personalized jewelry. Various alloy combinations allow customers to:

- Select metal combinations that complement their existing collections

- Incorporate symbolic meaning through metal choices (e.g., birthstone metals, anniversary commemorations)

- Create truly unique pieces that reflect individual style preferences

Manufacturing Implications:

This trend requires manufacturers to maintain diverse alloy inventories and develop production capabilities for smaller batch sizes and custom orders, representing both opportunity and operational complexity.

Strategic Implications for Manufacturers

Jewellery manufacturers must consider several strategic adjustments:

- Alloy Development Capabilities: Investing in metallurgical expertise to create proprietary lightweight and fusion alloys that differentiate product lines

- Design Versatility: Training artisans and CAD designers in mixed-metal techniques and developing production workflows that accommodate multi-metal fabrication

- Supply Chain Transparency: Building verifiable ethical sourcing systems as sustainability credentials become purchasing criteria

- Flexible Production: Developing systems that accommodate customization and smaller production runs without sacrificing efficiency

- Market Communication: Educating consumers about alloy innovation benefits—both technical advantages and sustainability impacts—to justify premium positioning

Conclusion

The 2025 jewellery manufacturing environment represents a convergence of technical innovation, shifting aesthetic values, and evolving consumer priorities. Mixed metals, lightweight fusion alloys, and sustainability-driven material choices define the current moment, all serving the broader theme of personalized expression through jewellery.

Manufacturers who successfully balance traditional craftsmanship with alloy innovation while meeting sustainability expectations position themselves advantageously in an increasingly discerning market. The trends identified here suggest the industry is moving toward greater material experimentation and consumer-centric design approaches that will likely continue shaping jewellery manufacturing beyond 2025.

BrandBuzz

Senco Gold & Diamonds Launches “SHAPE OF YOU”- AI Application for Women’s Day Celebration

A design-led innovation that interprets the language of the face to create a more intuitive and confident jewellery experience — beautifully framing the unique ‘Shape of You’.

In a world where words often take centre stage, Senco Gold & Diamonds — one of India’s leading pan-India jewellery retailers, with a legacy spanning over eighty-five years of trust — launches the Shape of You AI Application in celebration of Women’s Day. Built on refined karigari, design integrity, and a deep understanding of Indian aesthetics, Senco’s legacy now enters a new era where design intelligence meets personal insight.

Shape of You marks Senco’s first expert-led styling initiative, redefining how customers choose jewellery by aligning it with their unique face shape and natural features. Rooted in the belief that every face is distinct — and so should be the jewellery that adorns it — this innovation seamlessly blends technology with personalised styling. It enables customers to discover designs that genuinely complement their individuality. At its core lies Senco’s understanding that jewellery today is not merely an ornament, but an expression of identity and self.

For decades, jewellery has been chosen to complement what a woman wears. Now, Senco Gold & Diamonds invites women to choose jewellery that complements who they are. Introducing “The Shape of You” — an intuitive styling philosophy powered by technology — reimagining how jewellery is discovered, guided by the unique contours and character of each face. With The Shape of You, Senco Gold & Diamonds moves beyond conventional styling norms, placing the woman — not the trend — at the heart of design. The feature is now available across select Senco Gold & Diamonds showrooms and on the Senco app, offering women a more confident and considered way to choose jewellery.

Commenting on the same Joita Sen, Director & Head of Marketing and Design, Senco Gold and Diamonds, said, “Shape of You as an idea was conceived to enhance personal identity with technology led by design intuition. It is an innovation to help women understand themselves, their shapes better so that they can adorn themselves with jewellery that suits them best. It is an empowerment & personalisation tool for women”.

Commenting on the initiative, Suvankar Sen, MD & CEO, Senco Gold & Diamonds, said: “Often, women instinctively know when a piece of jewellery feels right, even if they cannot explain why. The Shape of You is one of our many technology applications for better customer experience and drive unique service to customers a one of its kind, and first time in jewellery industry”.

This Women’s Day Senco Gold & Diamonds also launched some exciting offers that are available across all our showrooms, which includes special flat discount on per 10gm of gold jewellery buying along (with upto 15% making charges* discount to celebrate women’s day), upto 15% on diamond value & upto 75% off on making charges on purchase of all diamond jewellery, (special offers for all women, girls, etc), upto 15% off on making charges (or MRP as applicable) of silver items (excluding coins) discount of upto 20% on leather items of sennes, etc.

Additionally, Senco Gold & Diamonds website will have online exciting offers for the customers which includes of upto 100% making charges off on buying of gold, diamond and platinum jewellery, on March 08, 2026 (1day offer ONLY).

-

BrandBuzz15 hours ago

BrandBuzz15 hours agoThe Pearl Edit: Thoughtful Women’s Day Gifting by GIVA

-

BrandBuzz15 hours ago

BrandBuzz15 hours agoAugmont Launches SPOT 2.0: One Platform. Every Product. Efficient Business

-

BrandBuzz19 hours ago

BrandBuzz19 hours agoSenco Gold & Diamonds Launches “SHAPE OF YOU”- AI Application for Women’s Day Celebration

-

National News19 hours ago

National News19 hours agoKushals Fashion Jewellery Curates Special Women’s Day Edit Celebrating Strength, Style and Self-Expression